Global Cable Industry 2026: How HONTA's Integrated Electroplating and Stranding Solutions Answer Surging Demand for High-Performance Conductors

Kunshan, China, January 2026 — As the global push for electrification and digital connectivity intensifies, the cable manufacturing sector faces unprecedented pressure to produce higher-quality, more durable, and more efficient conductors. A critical bottleneck has emerged in the pre-stranding phase: achieving flawless, uniform metal coatings at production speeds that match downstream processes. Industry leaders are now looking towards integrated, high-speed solutions that bridge the gap between coating and stranding. At the forefront of this technological convergence is HONTA, whose synergistic development of advanced electroplating equipment and High Speed bunching/stranding machine systems is setting a new operational paradigm.

The Industry Imperative: From Isolated Processes to Cohesive Production Cells

The traditional cable production line often treats wire drawing, coating (or plating), and stranding as separate, siloed operations. This disjointed approach leads to several inefficiencies:

- Speed Mismatch: A slow wire electrolytic plating line creates a bottleneck before a high-speed rigid frame stranding machine, underutilizing capital-intensive equipment.

- Quality Inconsistency: Manual transfers between processes increase the risk of surface contamination or damage, compromising the final conductor's performance.

- Operational Complexity: Managing multiple machine interfaces and material handling systems increases labor costs and error rates.

The solution, as championed by innovators like HONTA, lies in intelligent system integration. The goal is to create a seamless flow from a motorised pay off unit, through a high-speed plating process, directly into a precision stranding operation, all controlled by a unified data system.

HONTA's Technological Synergy: Electroplating Meets High-Speed Stranding

Founded in 2006, HONTA has built its reputation on a deep, dual expertise in both conductor finishing and forming technologies. This unique position allows the company to engineer solutions where the coating machine and the High Speed bunching/stranding machine are not just compatible but are co-optimized for peak collective performance.

1. The Precision Coating Foundation: Advanced Electroplating Lines

HONTA's electro plating machine portfolio is designed for speed, consistency, and material efficiency, forming the perfect precursor to high-speed stranding.

- High speed wire electrolytic plating line: Engineered for maximum throughput, this line minimizes process time while ensuring exceptional adhesion and uniformity of tin, nickel, or silver coatings.

- Specialized Single-Wire Lines: For applications requiring pristine quality, HONTA offers dedicated Ni electrolytic single wire plating line, Ag electrolytic single wire plating line, and Sn electrolytic single wire plating line solutions. These are critical for high-frequency data cables and specialized automotive wiring.

The consistent, high-quality output from these lines provides the ideal feedstock for HONTA's downstream stranding equipment.

HONTA's Wire Electrolytic Plating Lines ensure uniform coating, a critical pre-requisite for high-speed stranding.

2. The High-Speed Culmination: Intelligent Stranding Systems

Receiving the precision-plated wire, HONTA's stranding technology takes over. The company's flagship High Speed bunching/stranding machine is renowned for its stability and rotational velocity.

- Rigid Frame Stranding Machine: The robust construction of HONTA's rigid frame stranding machine eliminates frame deflection at extreme speeds, ensuring geometric precision in the final cable core. This is essential for impedance control in data cables.

- Integrated Material Handling: The stranding process begins with HONTA's sophisticated motorised pay off systems. These units provide precise, programmable tension control, feeding multiple wires simultaneously without tangles or breaks, which is vital for maintaining the integrity of the delicate plating.

This combination allows cable manufacturers to run their wire electrolytic plating line and stranding operations at their full, designed capacities without compromise.

Precision motorised pay off systems are key to feeding HONTA's high-speed stranders without damaging plated wires.

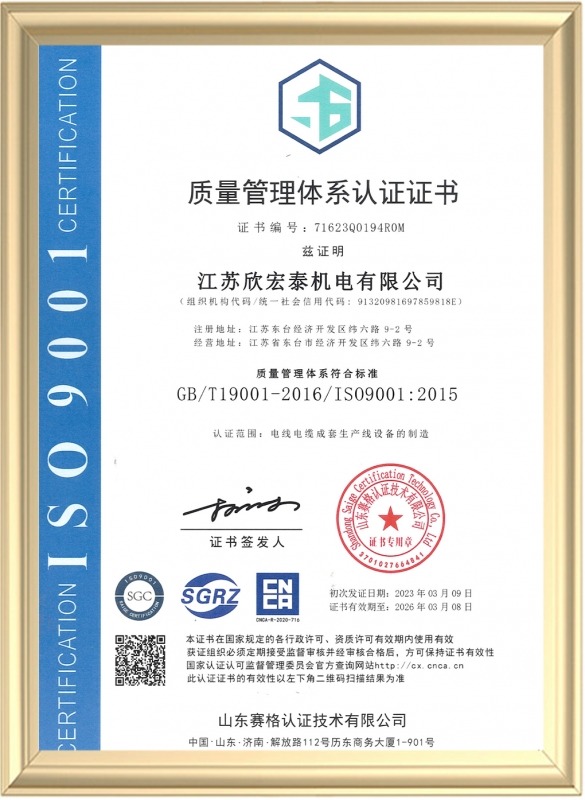

Certified Quality: The Foundation of Global Trust

HONTA's engineering excellence is underpinned by a rigorous commitment to international standards, providing customers with unwavering confidence in equipment performance and safety.

ISO 9001 Certification

Ensures a world-class quality management system for consistent design, production, and service.

ISO 14001 Certification

Demonstrates HONTA's dedication to environmentally responsible manufacturing processes.

UDEM International Certification

An independent validation of product performance, safety, and reliability for global markets.

Strategic Market Position and Global Reach

With its headquarters and main production base in Kunshan, China, and a strategic subsidiary, HONTA INC., established in the United States in 2017, the company is uniquely positioned to serve the global market. This dual-base structure allows for agile customer support, localized service, and a deep understanding of regional market needs from North America to Asia and Europe.

HONTA's product philosophy—emphasizing high speed, efficiency, automation, and human-centric design—resonates strongly with cable manufacturers investing in the future. Whether it's for EV charging infrastructure, 5G/6G network rollout, or renewable energy projects, the demand for perfectly plated and precisely stranded conductors is universal. HONTA's integrated approach, offering everything from the coating machine to the final High Speed bunching/stranding machine, provides a single-source, reliable solution.

Contact HONTA for Your Conductor Manufacturing Solutions

To learn more about how HONTA's integrated electroplating equipment and stranding machine technology can transform your production line, visit our website or contact our international team directly.

Email: tammy@jshonta.com

Phone: +86 182 6287 9467

WhatsApp: +86 187 5292 2675

WeChat: wtammy0631

Address: Room 1219, Building 3, Dongchuang Technology Center, Qianjin East Road, Kunshan City, Jiangsu Province, China. Zip: 215300

In conclusion, the next leap in cable manufacturing productivity will not come from incremental improvements to single machines, but from the holistic optimization of interconnected processes. HONTA, with its certified quality and pioneering work in synchronizing high speed wire electrolytic plating line technology with ultra-fast rigid frame stranding machine operations, is providing the blueprint for this integrated future. For industry stakeholders, engaging with a full-system provider like HONTA offers a clear path to overcoming current bottlenecks and capitalizing on the massive growth opportunities in the global cable market.